Over the past year, Ecosystm has conducted extensive research, including surveys and in-depth conversations with industry leaders, to uncover the most pressing topics and trends. And unsurprisingly, AI emerged as the dominant theme. Here are some insights from our research on the Healthcare industry.

Click here to download ‘AI in Healthcare: Success Stories & Insights’ as a PDF

AI is transforming the healthcare industry, offering unprecedented opportunities to improve patient outcomes and streamline operations. However, the successful implementation of AI in healthcare is not without its challenges. Those who can navigate these complexities and harness the power of AI will emerge as industry leaders, driving innovation and shaping the future of healthcare.

Despite the challenges, Healthcare organisations are witnessing early AI success in these 3 areas:

- 1. Diagnostics

- 2. Care Management

- 3. Operational Efficiency & Optimisation

Diagnostics

- Image Analysis. Analysing medical images (e.g., X-rays, MRIs) to detect diseases and abnormalities

- Diagnosis. Assisting clinicians in identifying and diagnosing diseases

- Early Detection. Detecting diseases at an early stage for more effective treatment

“Diagnostics is where our AI journey began – starting with image analysis for eye diseases, evolving to x-ray screening tools, and most recently, investing in digital stethoscopes for our doctors and nurses.” – CLINICIAN LEADER

Care Management

- Clinical Decision Support. Providing clinicians with recommendations and insights to improve patient care

- Personalised Treatment Plans. Personalising treatment protocols based on patient data and genetics

- Chronic Disease Management. Monitoring chronic diseases over multiple years

“Clinical decision support isn’t new, but AI has revolutionised it by enabling the system to send alerts and warnings proactively, rather than only when prompted.” – CLINICIAN LEADER

Operational Efficiency & Optimisation

- Supply Chain Management. Optimising inventory and supply chain processes

- Appointment Scheduling. Automating appointment booking and management

- Workflow Optimisation. Streamlining workflows and improving efficiency of clinical staff

“Patient satisfaction extends beyond clinical outcomes. Aspects like shorter waiting times during appointments, the availability of medications, and automated responses to common queries significantly enhance patient satisfaction. These are areas where we have successfully implemented AI.” – COO

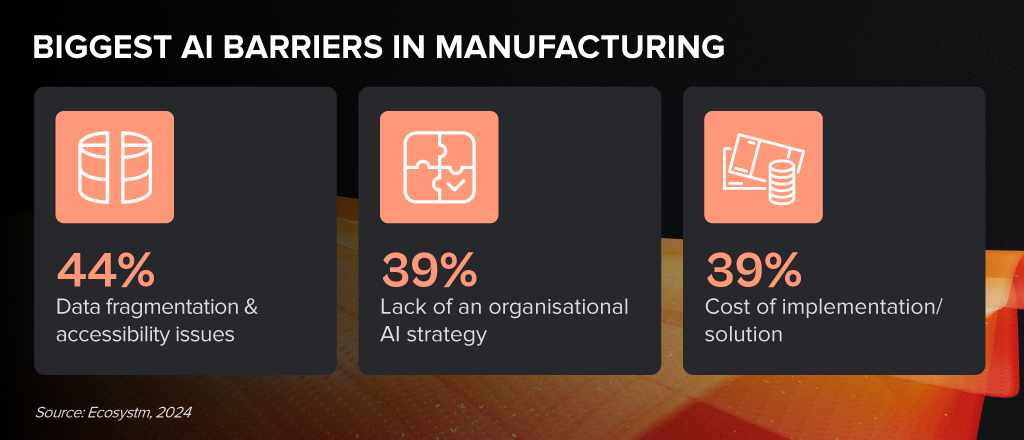

Over the past year, Ecosystm has conducted extensive research, including surveys and in-depth conversations with industry leaders, to uncover the most pressing topics and trends. And unsurprisingly, AI emerged as the dominant theme. Here are some insights from our research on the Manufacturing industry.

Click here to download “AI in Manufacturing: Success Stories & Insights” as a PDF

AI is revolutionising production lines, supply chains, and product development in the manufacturing sector. Yet, many manufacturers find themselves stuck between ambition and execution. Those who bridge this gap will gain a competitive edge, driving innovation and leading the industry forward.

Despite the challenges, Manufacturing organisations are witnessing early AI success in these 3 areas:

- 1. Quality Control & Assurance

- 2. Supply Chain Management & Optimisation

- 3. Process Automation & Efficiency

Quality Control & Assurance

- Defect Detection. Identifying defects in products and improving quality

- Product Inspection. Implementing AI-powered vision systems to inspect products and ensure they meet quality standards

- Data Analysis. Analysing operational data and customer feedback to identify operations and product issues

“AI is the future of design. It streamlines the design process, leading to faster time-to-market and superior products.” – OPERATIONS LEADER

Supply Chain Management & Optimisation

- Inventory Management. Optimising inventory levels and reducing costs

- Supply Chain Visibility. Gaining real-time visibility into supply chain operations

- Demand Forecasting. Predicting demand for products to improve production planning and inventory management

“By leveraging AI, we’re not just optimising our supply chain; we’re pioneering sustainable practices to reduce our carbon footprint.” – CIO

Process Automation and Efficiency

- Process Optimisation. Identifying areas for improvement and potential operational bottlenecks

- Predictive Maintenance. Predicting equipment failures and preventing downtime

- Customer Feedback Analysis. Analysing customer feedback to improve design processes, products, and services

“Our goal is to build intelligent manufacturing plants. By proactively monitoring equipment health, we minimise downtime and maximise productivity – we have set a new internal standard for operational efficiency in the last two years.” – HEAD OF PRODUCTION

AI has become a business necessity today, catalysing innovation, efficiency, and growth by transforming extensive data into actionable insights, automating tasks, improving decision-making, boosting productivity, and enabling the creation of new products and services.

Generative AI stole the limelight in 2023 given its remarkable advancements and potential to automate various cognitive processes. However, now the real opportunity lies in leveraging this increased focus and attention to shine the AI lens on all business processes and capabilities. As organisations grasp the potential for productivity enhancements, accelerated operations, improved customer outcomes, and enhanced business performance, investment in AI capabilities is expected to surge.

In this eBook, Ecosystm VP Research Tim Sheedy and Vinod Bijlani and Aman Deep from HPE APAC share their insights on why it is crucial to establish tailored AI capabilities within the organisation.

In my last Ecosystm Insights, I spoke about the implications of the shift from Predictive AI to Generative AI on ROI considerations of AI deployments. However, from my discussions with colleagues and technology leaders it became clear that there is a need to define and distinguish between Predictive AI and Generative AI better.

Predictive AI analyses historical data to predict future outcomes, crucial for informed decision-making and strategic planning. Generative AI unlocks new avenues for innovation by creating novel data and content. Organisations need both – Predictive AI for enhancing operational efficiencies and forecasting capabilities and Generative AI to drive innovation; create new products, services, and experiences; and solve complex problems in unprecedented ways.

This guide aims to demystify these categories, providing clarity on their differences, applications, and examples of the algorithms they use.

Predictive AI: Forecasting the Future

Predictive AI is extensively used in fields such as finance, marketing, healthcare and more. The core idea is to identify patterns or trends in data that can inform future decisions. Predictive AI relies on statistical, machine learning, and deep learning models to forecast outcomes.

Key Algorithms in Predictive AI

- Regression Analysis. Linear and logistic regression are foundational tools for predicting a continuous or categorical outcome based on one or more predictor variables.

- Decision Trees. These models use a tree-like graph of decisions and their possible consequences, including chance event outcomes, resource costs and utility.

- Random Forest (RF). An ensemble learning method that operates by constructing a multitude of decision trees at training time to improve predictive accuracy and control over-fitting.

- Gradient Boosting Machines (GBM). Another ensemble technique that builds models sequentially, each new model correcting errors made by the previous ones, used for both regression and classification tasks.

- Support Vector Machines (SVM). A supervised machine learning model that uses classification algorithms for two-group classification problems.

Generative AI: Creating New Data

Generative AI, on the other hand, focuses on generating new data that is similar but not identical to the data it has been trained on. This can include anything from images, text, and videos to synthetic data for training other AI models. GenAI is particularly known for its ability to innovate, create, and simulate in ways that predictive AI cannot.

Key Algorithms in Generative AI

- Generative Adversarial Networks (GANs). Comprising two networks – a generator and a discriminator – GANs are trained to generate new data with the same statistics as the training set.

- Variational Autoencoders (VAEs). These are generative algorithms that use neural networks for encoding inputs into a latent space representation, then reconstructing the input data based on this representation.

- Transformer Models. Originally designed for natural language processing (NLP) tasks, transformers can be adapted for generative purposes, as seen in models like GPT (Generative Pre-trained Transformer), which can generate coherent and contextually relevant text based on a given prompt.

Comparing Predictive and Generative AI

The fundamental difference between the two lies in their primary objectives: Predictive AI aims to forecast future outcomes based on past data, while Generative AI aims to create new, original data that mimics the input data in some form.

The differences become clearer when we look at these examples.

Predictive AI Examples

- Supply Chain Management. Analyses historical supply chain data to forecast demand, manage inventory levels, reduces costs and improve delivery times.

- Healthcare. Analysing patient records to predict disease outbreaks or the likelihood of a disease in individual patients.

- Predictive Maintenance. Analyse historical and real-time data and preemptively identifies system failures or network issues, enhancing infrastructure reliability and operational efficiency.

- Finance. Using historical stock prices and indicators to predict future market trends.

Generative AI Examples

- Content Creation. Generating realistic images or art from textual descriptions using GANs.

- Text Generation. Creating coherent and contextually relevant articles, stories, or conversational responses using transformer models like GPT-3.

- Chatbots and Virtual Assistants. Advanced GenAI models are enhancing chatbots and virtual assistants, making them more realistic.

- Automated Code Generation. By the use of natural language descriptions to generate programming code and scripts, to significantly speed up software development processes.

Conclusion

Organisations that exclusively focus on Generative AI may find themselves at the forefront of innovation, by leveraging its ability to create new content, simulate scenarios, and generate original data. However, solely relying on Generative AI without integrating Predictive AI’s capabilities may limit an organisation’s ability to make data-driven decisions and forecasts based on historical data. This could lead to missed opportunities to optimise operations, mitigate risks, and accurately plan for future trends and demands. Predictive AI’s strength lies in analysing past and present data to inform strategic decision-making, crucial for long-term sustainability and operational efficiency.

It is essential for companies to adopt a dual-strategy approach in their AI efforts. Together, these AI paradigms can significantly amplify an organisation’s ability to adapt, innovate, and compete in rapidly changing markets.

It is true that the Retail industry is being forced to evolve the experiences they deliver to their customers. However, if Retail organisations are only focused on creating digital experiences, they are not creating the differentiation that will be required to leap ahead of the competition. It is time for Retail organisations to leverage data to empower multiple roles across the organisation to prepare for the different ways customers want to engage with their brands.

Another trend that is creating a shift in the industry is the rise of small and medium-sized retailers. Traditionally, larger retailers have made larger investments in technology – they simply had deeper pockets for the on-premise investments. However, with the rise of SaaS, size may no longer be such an advantage in Retail.

Here is how organisations such as Walmart, Adobe, GoDaddy and Google are empowering the SME retailer.

Global supply chains were impacted early and badly by the COVID-19 pandemic. The fact that the pandemic started in China – the leader in the Manufacturing industry – meant that many enterprises globally had to re-evaluate their supply chain and logistics. This was compounded by the impact on demand – for some sectors the demand went down significantly, while in others, especially for items required to fight the crisis, there was an unexpected spike in demand. There was also the need for many manufacturers and retailers to shift to eCommerce, to directly access the market and sustain their businesses. These sudden shifts that were required of the industry, opened up the need for a global supply chain that is more integrated, agile and responsive.

Last week, global heavyweights with a stake in the global supply chain, joined a consortium to work on creating that agility. This includes PepsiCo, BMW, Shopify, DHL, and the United States Postal Service and some emerging tech companies. The alliance will actively work on solutions to embed automation and digitalisation in the logistics and supply chain systems. While this consortium was formed last year, recent events have accelerated the need to fix a global problem.

Co-Creation and Innovation

LINK is a collaborative ecosystem, co-founded by Innovation Endeavors and Sidewalk Infrastructure Partners (SIP) to bring together emerging tech start-ups, institutions and global organisations to innovate and make supply chains resilient. The tech start-ups involved include the likes of Fabric, that has large automated micro-fulfillment centres for faster deliveries, and Third Wave Automation, that has developed automated forklifts with enhanced safety measures.

LINK aims to transform global supply chains, with the use of technologies such as automation, IoT, AI, and Robotics. The solutions developed by the start-ups will be tested in real-life situations, often in large organisations with complex operations. On the other hand, the start-ups will have access to the internal systems of these large organisations to understand the data and their organisational needs.

Ecosystm Principal Advisor, Kaushik Ghatak says, “COVID-19 has brought the need for supply chain agility and resilience to a completely new level of criticality. Companies in the ‘New Normal’ will need higher levels of nimbleness and flexibility to be able to recover from this crisis quickly and sustain in an increasing disruptive world. Increased ability to sense and respond to disruptions will be key to success. It will require better visibility of their entire supply chain, increasing efficiencies, building necessary redundancies (in form of inventory and capacity) where they are required the most – redundancy comes at a cost – and being flexible and innovative to cater to the rapid market and supply-side changes. Rapid digitalisation to build such capabilities will be a key to success.”

“Managing such rapid changes is usually a struggle for organisations with large and complex supply chains, because of the years of past practices, systems and culture. For them Innovation is a must, but the path to innovation is difficult. The LINK collaboration model is the right step towards addressing that challenge. Collaborating with start-ups can infuse new ideas, more innovative ways of solving a problem and rapid testing of use cases in the areas of IoT, AI and automation.”

Involving Start-ups for Innovation

This initiative is a great example of how larger enterprises are looking to leverage innovations by the start-up community. The Financial Services industry has been an early beneficiary, when it stopped competing with Fintech organisations, partnering with them instead. Other industries have started to recognise the benefits of fast pivots and the role start-ups can play.

Ecosystm Principal Advisor, Ravi Bhogaraju says, “Bringing together companies that have complementary and unique capabilities to solve industry issues is a great way to speed up experimentation and innovation.”

However, he recognises that forming alliances such as this, comes with its own set of challenges. “One of the key things to recognise in such a construct is that the team members from different possessions bring with them their unique belief systems, organisational and country cultural constructs. Expectations on how things should work, can become quite tricky to navigate. The talent and expertise in such an environment need to be facilitated be able to deliver high quality outcomes.”

Talking about how these constructs can work successfully, delivering what started out to deliver, Bhogaraju says, “An agile team setup can help tremendously as it uses two key principles – People and Interactions over processes; as well as Working models over documentation.”

“A clear expectation setting through contracting at the beginning of the project cycle can help establish the ways of working and rules of engagement. Increased regular feedback and problem solving should continuously fine tune the ways of working. This way teams can get through the norming process at pace and scale and eventually focus on outcomes, rather than fumble over each other and/or have ego flareups.”

“The key is to get to creative problem-solving working cohesively – the intent being to challenge the status quo – stepping outside the box and using all capabilities within the team. Blending the subcultures together using agile way of working and principles, can be a fantastic way to make that happen – failing which you have the challenge of trying to somehow bring together different work products, people and preferences.”

Last week industry leaders, SAP and Siemens, announced a partnership to bring together their respective expertise on creating integrated and enhanced solutions for product lifecycle management (PLM), supply chain, service and asset management, in a move that is expected to accelerate Industry 4.0 globally.

The partnership between SAP and Siemens aims to develop innovative business models to break silos between manufacturing, product development and service delivery teams to establish seamless customer-centric processes. It will provide users with real-time business information, customer insights and performance data over the entire product development cycle.

As the first step of this agreement, Siemens will offer SAP’s Intelligent Asset Management solution and Project and Portfolio Management applications and SAP will offer Siemens’ PLM suite Teamcenter software for product lifecycle collaboration and data management to manufacturers and business operators across the network – complementing each other’s solutions.

Ecosystm Principal Advisor, Kaushik Ghatak says, “The convergence of the Information Technology (IT) and the Operational Technology (OT) worlds is a must for companies to operate in the cyber physical world of Industry 4.0. Historically, these two worlds have operated in silos. This is a great partnership announcement aimed towards meeting the convergence goals by integrating the capabilities of Siemens (an OT leader), and SAP (an IT leader). Together they would be able to offer an exhaustive set of very valuable offerings in the Digital Supply Chain and Digital Manufacturing domain for customers worldwide.”

Ghatak says, “This is not the first such partnership for Siemens. A strategic alliance between Siemens and Atos has been in place since 2011. In 2018 the alliance was strengthened with plans to accelerate their joint business until 2020, with a focus on building innovative solutions by combining their capabilities. However, the difference this time is that SAP has very a deep and wide set of software offerings in the supply chain and manufacturing domains, which when stitched together with Siemens’ PLM solutions can provide true end-to-end digitalisation capabilities across the ‘Design, Source, Make, Deliver and Plan’ continuum of the value chain.”

Ecosystm Comments

Ghatak, however, cautions that while this is a great partnership announcement between two giants in their respective fields, they will need to collaborate actively on three key aspects for this partnership to deliver value for the customers.

- Product Development. Building-integrated solutions with heterogenous data models is not easy. It will require very open collaboration between their product development teams to identify the use cases and build solutions that can enable seamless information flow and actions across the different software modules owned by each.

- Go-to-market. Going to market jointly will need strong collaboration too. In terms of the agreement on customer account ownership, pricing, sharing of pre-sales resources and so on.

- Implementation. And, last but not the least, it will require collaboration to ramp up the implementation capabilities of the jointly developed solutions.