Over the past year, Ecosystm has conducted extensive research, including surveys and in-depth conversations with industry leaders, to uncover the most pressing topics and trends. And unsurprisingly, AI emerged as the dominant theme. Here are some insights from our research on the Retail industry.

Click here to download ‘AI in Retail: Success Stories & Insights’ as a PDF

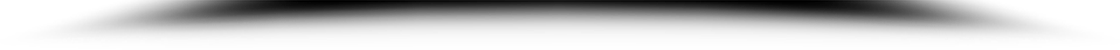

From personalised product recommendations to predictive analytics, AI is helping retailers deliver exceptional customer experiences and optimise their operations. However, many retailers are still grappling with the complexities of AI implementation. Those who can successfully navigate this challenge and harness the power of AI will emerge as industry leaders, driving innovation and shaping the future of retail.

Despite the challenges, Retail organisations are witnessing early AI success in these 3 areas:

- 1. Customer Experience & Engagement

- 2. Supply Chain Optimisation

- 3. Fraud & Risk Analysis

Customer Experience & Engagement

- Conversational AI. Providing real-time customer support and answering queries

- Personalisation. Offering tailored product suggestions based on customer preferences and behaviour

- Virtual Try-On. Allowing customers to visualise products in different settings using AR

“AI has helped us to refine our customer chatbots to allow for more self-service. We’ve experienced faster customer order processing and quicker resolution of issues, putting control directly in the hands of our customers.” – CX LEADER

Supply Chain Optimisation

- Inventory Management. Automating inventory management processes to ensure optimal stock levels

- Supply Chain Visibility. Monitoring and optimising supply chain operations, including logistics and distribution

- Demand Forecasting. Predicting sales and demand trends to optimise inventory and production planning

“We use AI to optimise the supply chain, saving operational costs. Digital supply chains and cloud-based tracking systems streamline operations and enhance efficiency.” – CFO

Fraud & Risk Analysis

- Fraud Detection. Identify and prevent fraudulent activities, such as online fraud and chargebacks

- Risk Assessment. Assessing risk factors associated with customer transactions and preventing losses

- Customer & Market Insights. Understanding customer behaviour, market trends, and growth opportunities

“With eCommerce as a key market force, understanding customer habits is crucial to ensuring we have the right products in stock and optimising our pricing strategy.” – COO

Over the past year, Ecosystm has conducted extensive research, including surveys and in-depth conversations with industry leaders, to uncover the most pressing topics and trends. And unsurprisingly, AI emerged as the dominant theme. Here are some insights from our research on the Manufacturing industry.

Click here to download “AI in Manufacturing: Success Stories & Insights” as a PDF

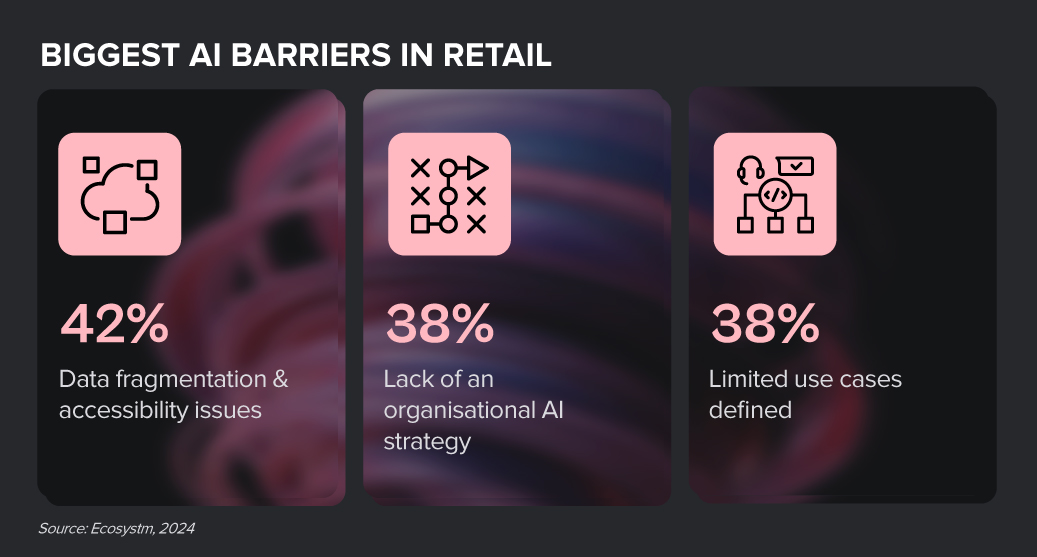

AI is revolutionising production lines, supply chains, and product development in the manufacturing sector. Yet, many manufacturers find themselves stuck between ambition and execution. Those who bridge this gap will gain a competitive edge, driving innovation and leading the industry forward.

Despite the challenges, Manufacturing organisations are witnessing early AI success in these 3 areas:

- 1. Quality Control & Assurance

- 2. Supply Chain Management & Optimisation

- 3. Process Automation & Efficiency

Quality Control & Assurance

- Defect Detection. Identifying defects in products and improving quality

- Product Inspection. Implementing AI-powered vision systems to inspect products and ensure they meet quality standards

- Data Analysis. Analysing operational data and customer feedback to identify operations and product issues

“AI is the future of design. It streamlines the design process, leading to faster time-to-market and superior products.” – OPERATIONS LEADER

Supply Chain Management & Optimisation

- Inventory Management. Optimising inventory levels and reducing costs

- Supply Chain Visibility. Gaining real-time visibility into supply chain operations

- Demand Forecasting. Predicting demand for products to improve production planning and inventory management

“By leveraging AI, we’re not just optimising our supply chain; we’re pioneering sustainable practices to reduce our carbon footprint.” – CIO

Process Automation and Efficiency

- Process Optimisation. Identifying areas for improvement and potential operational bottlenecks

- Predictive Maintenance. Predicting equipment failures and preventing downtime

- Customer Feedback Analysis. Analysing customer feedback to improve design processes, products, and services

“Our goal is to build intelligent manufacturing plants. By proactively monitoring equipment health, we minimise downtime and maximise productivity – we have set a new internal standard for operational efficiency in the last two years.” – HEAD OF PRODUCTION

During this pandemic, shoppers who have experienced new forms of delivery direct from manufacturers, curbside pickup and eCommerce via wholesalers will likely adopt at least some of those habits in their everyday lives in future. Why? Ease of use, convenience, hygiene and guaranteed product availability, all factor into this shift.

Most retailers were not ready for a rush of online shoppers or structured for a Buy Online Pickup In-Store (BOPIS) model. They struggled to pivot with their own delivery set-up, both in terms of staffing and infrastructure. Delivery slots were rare and required midnight countdowns to the next day’s set of slots with online confusion. Many grocery retailers initially stopped curbside deliveries due to lack of resources for fulfilment in store.

And for SME retail outlets, square meterage limits the number of customers inside at a time and social distancing measures limit handling curbside pickups. Supply chain issues and inventory management also played a role, with local inventory visibility a real factor in determining order placement.

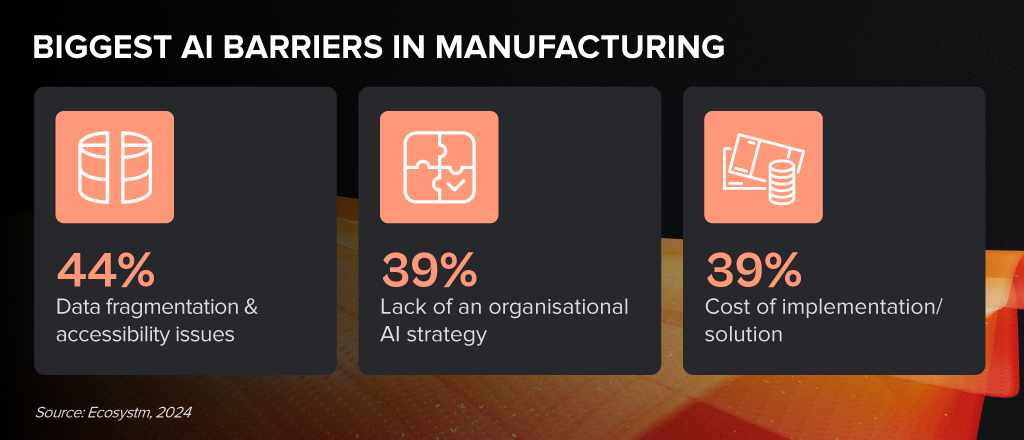

As shown in Figure 1, Ecosystm research shows that supply chain optimisation and demand forecasting are both listed in the top five business solutions that firms in retail consider using AI for.

Hybrid Operations

How can retail firms, with both perishable and non-perishable goods, use AI, automation and other infrastructural investments to develop the near-term future of curbside retail? We suggest the use of hybrid operations.

Retailers are starting to look at developing hybrid operations: part retail space and part fulfilment centre. Allowing customers to enter only part of the store or pulling inventory off the shelf to a different part of the store for deliveries expands reach and allows fulfilment without decreasing the experience for customers who prefer to shop in-store. But it requires an IT infrastructural upgrade to make it happen.

In the medium term, leveraging automation will be one of the ways supermarkets and other retailers evolve their models to remain viable and profitable.

What can be automated?

Let’s define these automated delivery infrastructural options:

- Curbside pickup is the endpoint of manual sorting and selecting operation, and then the goods are ready for pickup with a vehicle outside the store.

- Micro-fulfilment centres are locations with a logistics company to maximise space in traditional stores and expand online options. Micro-fulfillment helps retailers solve the labour and last-mile costs conundrum as it brings the goods closer to the end customer.

- Dark stores are traditional retail stores that have been converted to local fulfilment centres.

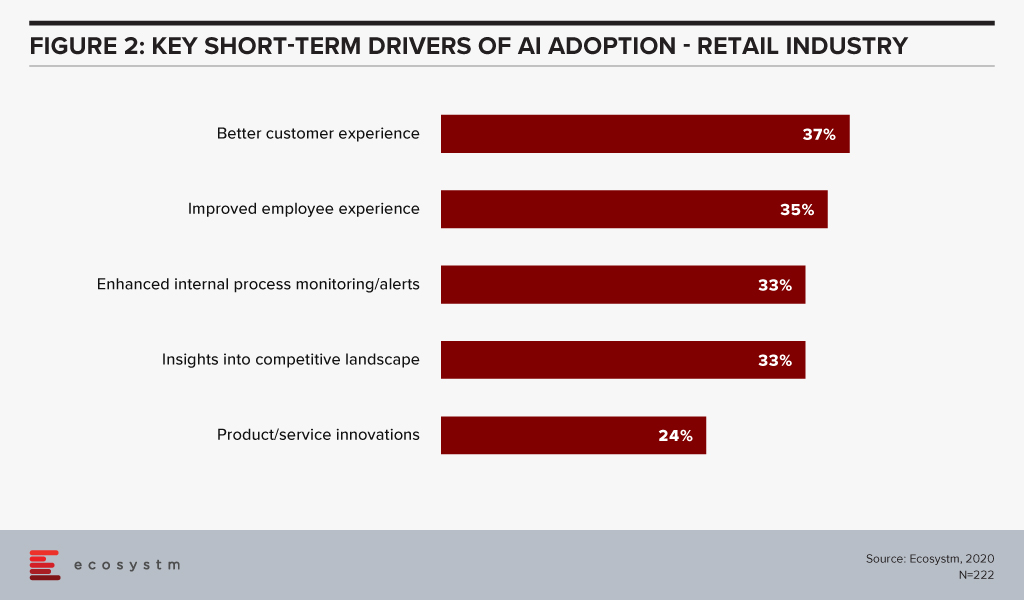

None of these concepts are new, but as alternatives to traditional retail in the current environment, they are viable options. Having curbside pickup, micro-fulfilment centres or dark stores help ease transitions towards traditional operations while still protecting customers and employees. Figure 2 from our AI research at Ecosystm shows that better customer experience is a top short-term driver in retail AI deployment.

Restructuring the three factors of production

By using AI and inventory automation, retailers can focus on rightsizing the three factors of production:

- Labour. Reducing the staffing cost to produce the same volume of sales.

- Inventory. Giving the retailer the tools to replenish stores with more specific information on consumption and wastage.

- Physical Space. Enabling dynamic adjustments of product display allows alignment more closely with sales patterns within the physical store. This can be adjusted for within the week and even by day.

Retailers are looking to speed delivery by dispersing inventory closer to customers. They use automation to build more compact distribution operations by using hybrid operations.

Designing hybrid operations with technology

To develop a hybrid operation, what IT infrastructural elements need to be addressed?

Store layout. Hybrid operations should drive efficiency in delivery, based on time and motion, but without impacting in-store shoppers. Order pulling should structurally happen towards the back of the store, both for efficiency and ease of access to move goods. To maintain product quality, networks and sensors need to be installed.

Process training. Hybrid operations are system dependent. Skilled staff who pick items for delivery require systems that implement standard procedures for selection and bundling. Processes require system automation for checks to mitigate high levels of wastage. Operational implementations need to include systems that manage cut-off times and back-room management.

Order management and inventory management systems. Analytics help retailers to stock popular items. They can then ensure these are easily accessible both front and back of the store. Retailers need to prioritise inventory management to make the most of inventory visibility across hybrid operations. SKUs and barcodes should be simple, consistent and unique.

Learning from innovative IT models in Grocery

In California, Sysco expanded its direct-to-the-consumer pop-up format to help give shoppers in the area access to fresh grocery items. Whole Foods expanded its dark store concept in Texas in combination with Amazon. Aldi in the UK rolled out an online program to distribute grocery parcels to consumers who were self-isolating, with 22 different goods in the bundle including toilet paper and anti-bacterial gel.

Market ownership will come from a better shopping experience. Streamlining processes and automating order fulfilment using IT in a hybrid retail operation could help lessen the financial and logistical strain of maintaining social distancing and proper hygiene measures.