IoT, Industry 4.0, Industrial IoT (IIoT), odds are that you have heard these terms used around you recently. IoT in the consumer space is a pretty straightforward concept to understand. IoT is an interconnected world of computing, mechanical and digital devices such as in a smart home consisting of thermostats, webcams, smoke detectors, smart doorbells who can talk to each other and managed from the internet or a smartphone.

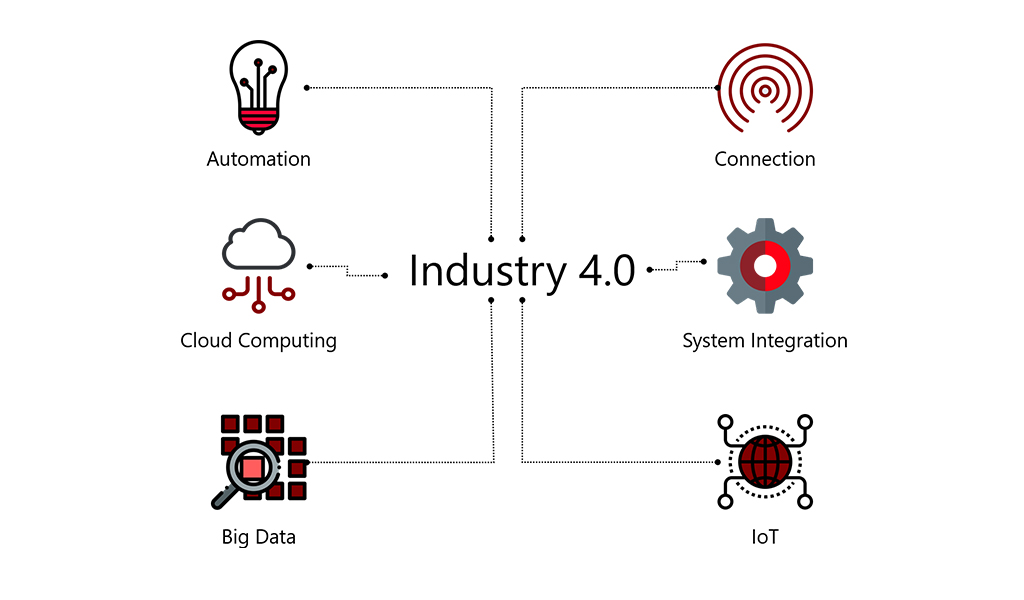

On the other hand, when we look at things at a larger scale or we can say, an “industrial scale” then it is a whole new IoT world. Industrial internet of things (IIoT) is an extension of IoT and is the use of IoT largely in manufacturing applications, and supply chain management. IIoT is driving the next wave of the industrial revolution or we can say it’s opening a gateway to ‘Industry 4.0’. The key idea driving Industry 4.0 is a connected world comprising humans, machines, sensors and data working together in real-time to transform business and manufacturing processes.

A traditional manufacturing environment application works by connecting machines to a centralised data centre. The pain points here are there isn’t any interconnection between machines, the latency rate is high and processes are manual and thus prone to errors. Contrary to this, IIoT puts a modern approach and makes processes decentralised. IIoT makes machine interconnection possible converting them into automated and smart processing units. With IIoT machines have the ability to talk to each other in their own Machine to Machine(M2M) language.

The basic components that drive an IIoT system are:

- Secure intelligent assets such as sensors and smart controllers – that can sense, communicate, store and transmit information

- Communication and data storage infrastructure – often cloud-enabled

- Data analytics and smart business apps that generate information from the data

- Skilled workforce

How IIoT Can Revolutionise an Industry

IIoT is transforming the manufacturing industry and other supply chain intensive industries by maximising efficiency, reducing downtime and increasing the overall production. While IIoT adoption is still in a nascent stage, there are some industries that have taken the first mover advantage and have started demonstrating readiness use cases.

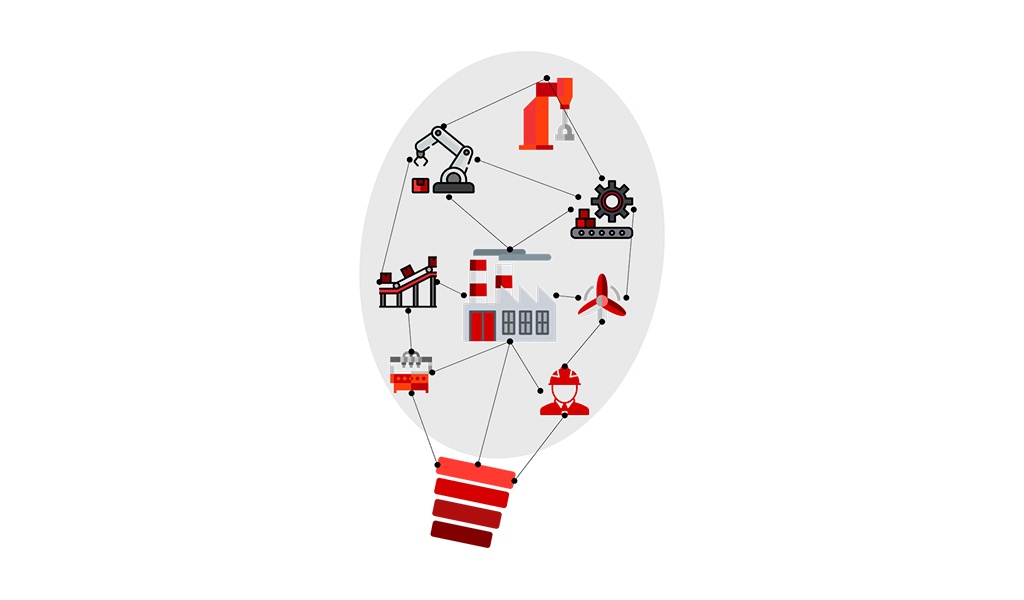

The Smart Factory

The adoption of IIoT has reshaped traditional factories to create smart factories. The systems work with interconnected machines and real-time data exchange that merge the departmental communications along with unified operations and information systems.

How is IIoT making factories ‘smart’?

IIoT has revamped how the traditional units worked. The slow and manual processes are now automated processes with M2M communication. This can be easily demonstrated through an example of how Smart Factories deal with preventive maintenance.

A smart factory has machines, sensors, databases, and humans all working in sync with each other. Sensors within machines can automatically notice a fault and the software logic sends an automatic alert to the right human to analyse the cause behind the fault. With Artificial Intelligence incorporated, machines determine the cause of the faults and go beyond predictive to prescriptive approach pre-empting problems before they exist. This in return reduces the maintenance cost and increases uptime of the factory by introducing parameters to fix machines with accuracy. In-return this leads to increased shelf-life of components and less-time involved in problem detection and rectification.

Energy & Utilities

The Oil & Gas industry is embracing IIoT with a multitude of benefits. Now the energy and utilities have an ability to easily sync data and simultaneously operate across multiple locations. This is made possible with the adoption of cloud, and installation of sensors that capture real-time data on the operating conditions of assets, monitor physical conditions such as temperature, pressure and humidity, and even environmental conditions. The practical scenario here is that Oil & Gas companies are remotely controlling their drills and monitoring the earth’s crust by remote control sensors and maintaining the flow of resources.

Logistics

With so many moving parts in a logistics system, from factories, collection points, and the transport network, it was difficult to maintain and manage a single view of the entire process. Through an ecosystem of sensors on the machines and vehicles covering the entire supply chain, it is now possible to access real-time data. It allows advanced functionalities such as virtually positioning hundreds of vehicles and optimising their route. In the process saving energy and reducing the time for delivery. The consequence is reduced costs for fuel, vehicle maintenance, and staff, plus increased customer experience through shorter and more accurate delivery times.

Other Industries – Promising the change

The adoption of IIoT will go beyond the early adopters and revolutionise several other industries. The Transportation industry is ripe for transformation given that infrastructure is being strained and margins reduced. The challenges of demand and aging infrastructure can be best handled by IIoT.

“The success of smart cars will eventually depend on how ‘smart’ the infrastructure is,” opines Vernon Turner, Executive Analyst, Ecosystm. “Several smart cities are already thinking along these lines, and adoption of IoT in Transportation is set to rise exponentially.”

Another industry that will benefit immensely from IIoT adoption is Healthcare. At the moment, asset management IoT systems have been adopted by several organisations, as in-patient remote monitoring systems that allow clinicians to monitor and analyse patient data remotely.

“The real value of IoT will be realised when clinicians have a clear workflow that allows them to monitor patients outside the hospitals,” says Sash Mukherjee, Principal Analyst, Ecosystm. “In the past, healthcare organisations have been influenced by the Manufacturing industry – by Lean and Six Sigma. They will benefit from implementing Industry 4.0 technologies, that will transform not just the provider organisations, but healthcare in general.”

Turning IIoT into a Profit Engine

Given all of this information about IIoT you may be thinking about the ROI, associated costs, benefits and the industry-wide exposure of the Industrial IoT. It is imperative that companies large & small are embracing Industry 4.0 change. IIoT is benefitting businesses through differentiated offerings, a creation of newer revenue streams and increased monetisation of existing offerings.

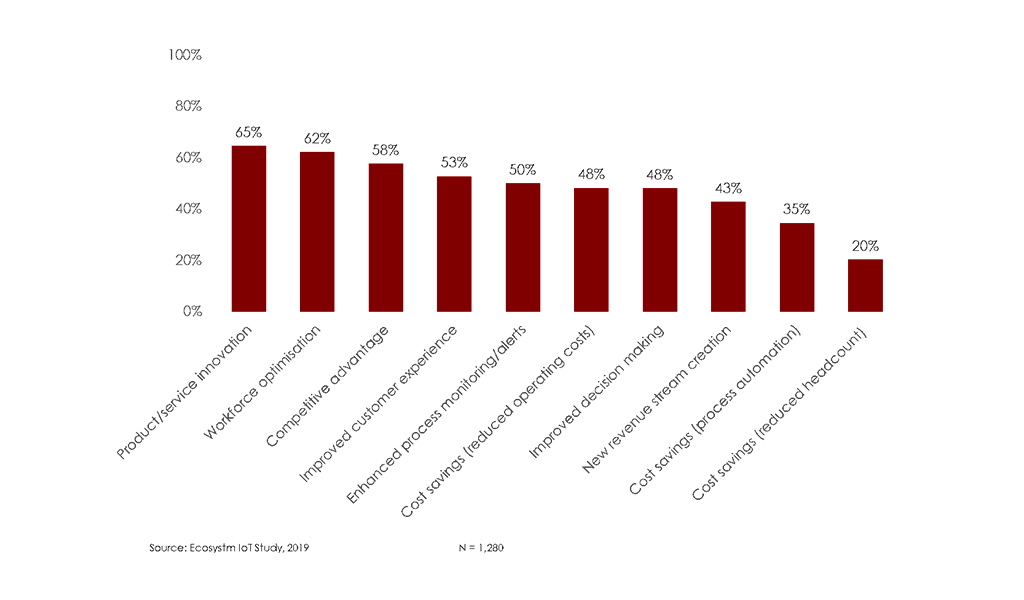

The Ecosystm IoT Study, 2019 looks at the drivers of IoT adoption across industries.

The data shows that the key drivers of IoT adoption can all affect the profit margin of an organisation.

- Innovation. In today’s competitive world, innovation in product designing and service delivery is directly related to a positive impact on profit margins. Organisations are looking beyond cost savings through their investments in IoT and are using IIoT to bring new, innovative products and services to the market. They are looking at creating innovative businesses that can leverage technology and offer cost savings.

- Workforce Optimisation. It is impossible to bring change without workforce optimisation. Organisations are working on the valuable insights offered by IIoT systems which further provide ways to optimise the workforce and accelerate productivity. Implementation of automated production units and the reduction of manual labour is bringing both productivity gains and increased profits. It is also boosting employee morale – happier employees impact the profitability of organisations, reduces turnover, improves customer interactions, and promotes more job ownership.

- Customer Experience. Customer expectations have gone up and so have methods to improve customer experience. Organisations are taking IIoT seriously, as it’s unleashing capabilities to improve processes throughout the product life cycle while also improving product quality through better QCs. Feedback to product improvement time has reduced – customer features and product improvement requests can now be handled more efficiently, based on customer data.

Businesses that fully capitalise on IIoT systems are successfully building a competitive edge through their innovative products, optimised workforce, and differentiated products and service offerings to enhance customer experience.

What Lies Ahead?

As IIoT percolates into other industries, we will potentially see a new industrial revolution. This has obviously been attracting investment and technology companies quickly to offer related technology offerings that tech buyers would do well to consider along with IoT.

Cloud

Data management will become an obvious challenge with IIoT-driven data proliferation. Already the industry has been talking about going beyond cloud to “fog” computing. The real value of IIoT will be realised when the solutions become able to operate on the Edge. This will see an increased uptake of SaaS offerings that will be required for quick and accurate data-driven decisions.

AI

AI will eventually go further than basic machine learning and incorporate deep learning for better predictive and prescriptive analysis. IoT devices with embedded AI will truly revolutionise industries. This is another technology area that tech buyers should keep an eye on, irrespective of the industry.

Security and Risk Management

An explosion of IIoT devices and data will bring new risks. Cybersecurity experts and teams will be required to constantly monitor vulnerabilities, follow security best practices and eventually predict breaches.

The Future

Industry 4.0 is very much a buzzword in certain industries, with several advanced organisations already following the business and technology practices. Naturally, there are still many companies that do not see the need for new technology or would rather invest in other areas.

For organisations that are looking to modernise, innovate and remain competitive, Industry 4.0 is a good benchmark of how technology can be leveraged. IIoT is a key enabler of Industry 4.0 and has the potential to deliver benefits to majority industries through increased intelligence and curated data – the question is how soon we can witness it on a scale.